Your shopping cart is empty!

Industry 4.0 Training Kit: Embracing the Future of Industrial Automation

By Ir. Dr. Hudyjaya Siswoyo Jo

As we move towards Industry 4.0, the need for seamlessly integrated and intelligent systems in manufacturing becomes more critical than ever. This is where the Industry 4.0 Training Kit comes in, providing a hands-on learning experience for students in the Robotics & Mechatronics Engineering program at Swinburne Sarawak.

System Overview:

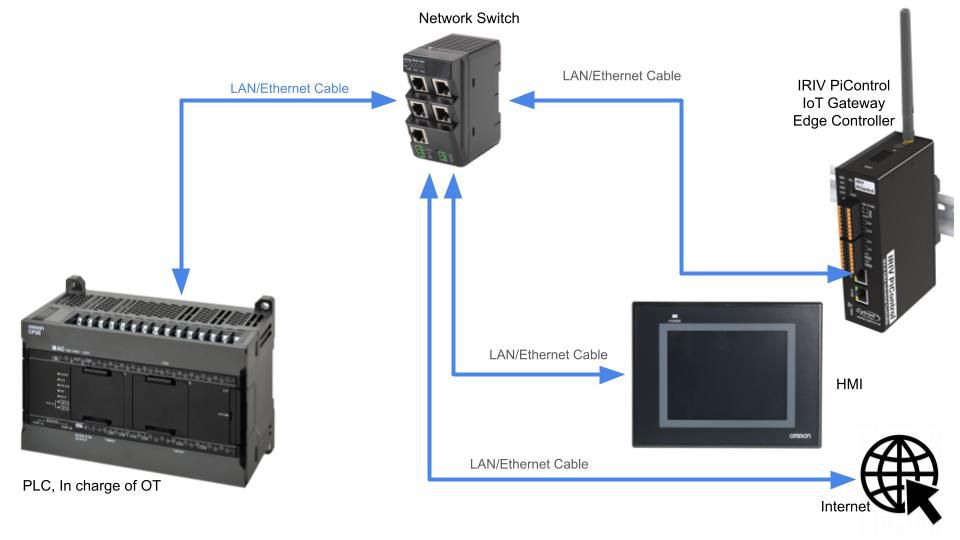

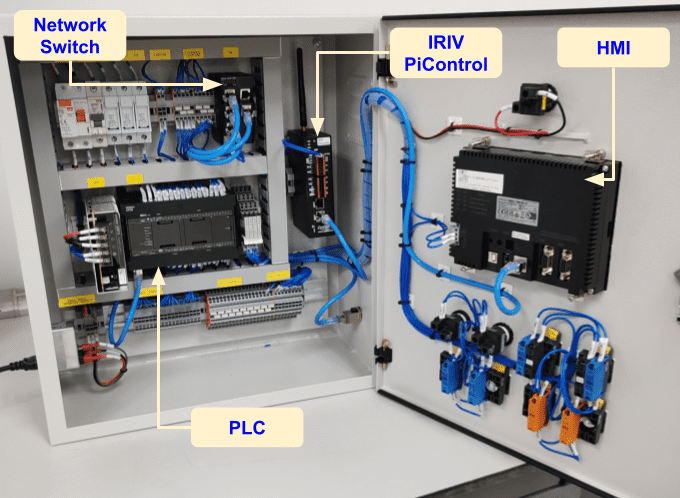

The PLC in this Industry 4.0 Kit is in charge of Operational Technology, interfacing actuators, and sensors. The IRIV PiControl will be the IoT Gateway. There is also a HMI (Human Machine Interface) for real-time system status display. All these three main controllers are interconnected via a network switch, using Ethernet cables.

Bridging the Gap Between Industrial Automation and Data:

The core of this training kit is the IRIV PiControl, a versatile device with dual functionality:

- IoT Gateway: IRIV PiControl acts as a bridge between the factory automation system's programmable logic controller (PLC) and the connected cloud or local storage. This allows for real-time data extraction and exchange, enabling critical insights into production processes.

- Edge Processor: Equipped with OpenCV and Python, IRIV PiControl transforms into an edge processor capable of performing basic machine vision tasks. This opens up possibilities for simple counting, quality inspection, and other image-based automation applications, directly on the factory floor.

Software Stack:

To power this multi-faceted functionality, the training kit utilizes:

- Node.js and Node-RED: These JavaScript-based platforms provide a user-friendly environment for building complex IoT applications, handling data flows, and visualizing real-time information.

- OpenCV with Python: This powerful combination equips IRIV PiControl with machine vision capabilities, allowing for image processing, feature detection, and object recognition, all within the edge computing framework.

Data Storage and Accessibility:

The training kit offers flexibility in data storage, catering to both cloud and local needs. This ensures data availability for analysis and decision-making, whether real-time monitoring or offline investigation. IRIV PiControl is a good candidate as a local server too. It can expand the storage by adding an M.2 NVMe SSD (manual installation is needed).

Future-Proofing Education:

The Industry 4.0 Training Kit is designed to equip students with the essential skills and knowledge required to thrive in the ever-evolving landscape of industrial automation. With a focus on cutting-edge technologies like IoT, edge computing, and machine vision, this training program bridges the gap between theoretical understanding and practical application, preparing students for success in the Industry 4.0 workforce.

Timeline and Availability:

Currently in the design stage, the Industry 4.0 Training Kit is scheduled for delivery in 2025, primarily catering to the Robotics & Mechatronics Engineering program at Swinburne Sarawak. This innovative training platform will be housed in the Robotics Lab, providing students with a dedicated environment for hands-on learning and experimentation.

Conclusion:

The Industry 4.0 Training Kit represents a significant step forward in engineering education, equipping students with the tools and knowledge necessary to contribute to the future of intelligent manufacturing. By integrating industrial-ready, open-platform edge controllers like IRIV PiCotnrol, this training program paves the way for a new generation of engineers prepared to navigate the complexities and opportunities of Industry 4.0.

Related Products

IRIV PiControl - IR4.0 CM4 Industrial Controller

S$420.00++ S$420.00

IRIV PiControl Wireless 2GB RAM 16GB eMMC

S$420.00 S$420.00

IRIV PiControl Wireless 4GB RAM 32GB eMMC

S$453.00 S$453.00

International

International Singapore

Singapore Malaysia

Malaysia Thailand

Thailand Vietnam

Vietnam